Building Resilient Supply Chains: A 2024 Perspective

Written By

Arun Dev Kumar, Manager – Supply Chain Solutions & Products.

25th September 2024

In 2024, global supply chains face new, persistent disruptions. Geopolitical tensions, climate change, and technological vulnerabilities continue to test the strength of supply chains worldwide, and businesses must pivot to handle these emerging challenges effectively.

The Russia-Ukraine war, China-Taiwan tensions, and other global geopolitical conflicts have created unprecedented risks for supply chains. During the pandemic, organizations realized the fragility of global supply chains that rely heavily on single-source suppliers, particularly for critical materials like semiconductors and rare earth elements.

Today, companies need to diversify their sourcing strategies, embracing multi-supplier models to reduce dependence on any one region. This resilience tactic enables faster adaptation to unforeseen geopolitical challenges. However, managing multiple suppliers across different regions introduces complexities that require advanced supply chain management systems, including predictive analytics and real-time visibility tools to monitor risks as they arise.

The impact of climate change on supply chains is becoming more evident every year. Extreme weather events—droughts, hurricanes, and wildfires—are increasingly disrupting key transportation routes. The Panama Canal, a crucial artery for global shipping, recently experienced its driest year in over a century, leading to significant shipping delays and rerouting.

In response, companies must adopt environmentally adaptive strategies. This includes recalibrating logistics networks, building redundancy into routes, and investing in technologies that predict weather disruptions and mitigate risks. Sustainability is no longer just a regulatory requirement; it’s a resilience strategy that enhances long-term business viability. ESG (Environmental, Social, Governance) initiatives are becoming increasingly important, with businesses needing to align resilience efforts with these broader corporate goals.

With the rapid digitization of supply chains comes a heightened risk of cyber-attacks. The past few years have seen an alarming increase in cyber threats targeting industries across the board, from healthcare to automotive. In 2023 alone, we saw a 62% rise in cyber incidents, with major attacks like the MOVEit Data Breach impacting over 1,000 businesses.

A resilient supply chain in the digital age demands that businesses prioritize cybersecurity, ensuring that data is protected across all touchpoints. Blockchain technology, for example, can help by providing a transparent and secure ledger that mitigates the risk of tampering. As supply chains become more interconnected, protecting the digital infrastructure is as critical as managing physical supply chain assets.

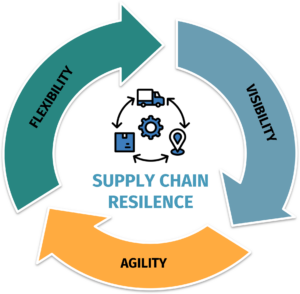

Flexibility has become the backbone of modern supply chain resilience. In times of crisis—whether due to geopolitical disruptions or infrastructure failures—companies that can pivot their logistics operations thrive. The Baltimore bridge collapse highlighted this, with truckers and logistics managers having to re-route operations while still meeting delivery timelines.

Supply chain leaders must build flexibility into both their transportation networks and supplier relationships. Whether this involves shifting from maritime to air freight during a shipping bottleneck or increasing storage capacity to buffer against disruptions, the key is to have alternative plans in place that allow for quick adaptation.

Predictive analytics, AI-driven insights, and real-time visibility have transformed how organizations approach supply chain resilience. Where companies once responded to disruptions reactively, advanced technologies now allow them to anticipate and mitigate risks before they occur. For instance, digital twins—virtual models of supply chain networks—enable businesses to simulate disruptions and optimize their operations proactively.

The rise of IoT (Internet of Things) further enhances visibility across the supply chain, providing real-time data on everything from equipment performance to shipment tracking. With more granular data, organizations can foresee potential bottlenecks and make decisions swiftly, ensuring minimal disruption to operations.

As we look ahead, supply chain resilience will be defined by adaptability, data-driven decision-making, and sustainability. While the risks of geopolitical upheaval, climate change, and cyber threats persist, businesses that adopt a proactive and flexible approach to managing their supply chains will be better equipped to handle the next wave of disruptions. By leveraging technology, diversifying supply bases, and embedding sustainability into their operations, organizations can build a supply chain that not only survives disruptions but thrives amid them.