HARNESSING ANALYTICAL PROWESS: KEY SUCCESS STORIES FROM OUR ANALYTICS ENGAGEMENTS

India

Industry: Manufacturing

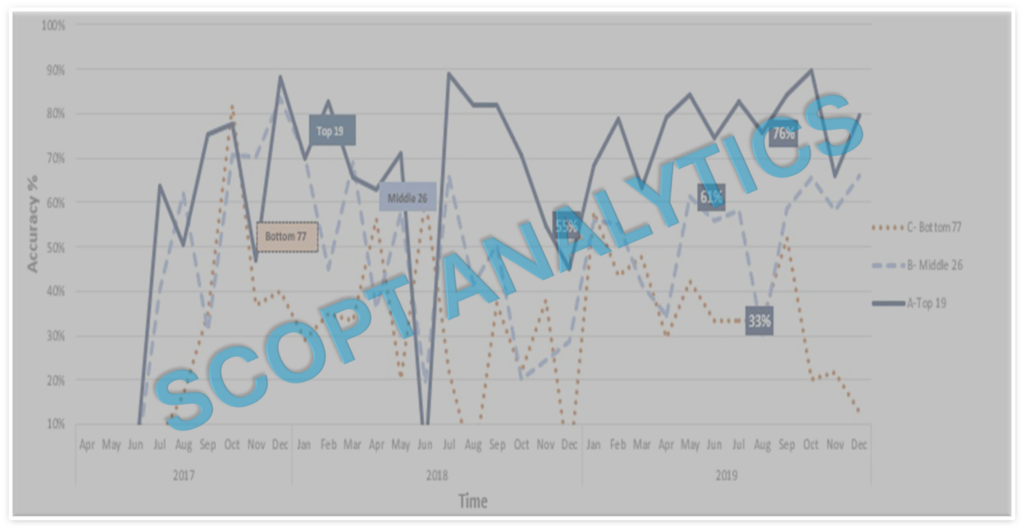

Business Challenge: An Indian manufacturer of electrical and telecommunication cables struggled with low order fulfillment rates and high inventory levels due to inaccurate demand forecasting and an underdeveloped S&OP process. They needed a solution to effectively align demand, production, and inventory.

Solution: We implemented a Python-based demand forecasting solution at the SKU-branch level, generating rolling 6-month forecasts. A commodity price simulator was developed to assess real-time demand fluctuations. Additionally, tailored demand planning and S&OP processes were introduced, along with KPIs for tracking forecast performance.

Business Results: The solution led to a 10-12% increase in forecast accuracy and an 18-20% reduction in inventory, while also streamlining communication and aligning incentives across sales, marketing, and operations teams.

USA

Industry: Consumer Packaged Goods (CPG)

Business Challenge: An American multinational confectionery and snack food company needed to optimize re-order points and base stock levels for each SKU at the branch and regional distribution centers (RDCs). The goal was to fulfil customer orders within 72 hours while minimizing the ‘CUT Rate’ to ensure better product availability and customer satisfaction.

Solution: We developed a simulation module to model demand, supply chain processes, and replenishment orders based on historical forecasts and errors. Using Monte Carlo simulations, we ran 3,000 to 4,000 iterations to optimize re-order points and base stock levels, minimizing cut rates across regional distribution centers and branches.

Business Results: We achieved a 3.9% improvement in fulfilment rates at the SKU branch and RDC levels while reducing held inventory from 64 days to 48 days.

India

Industry: Fast Moving Electrical Goods (FMEG)

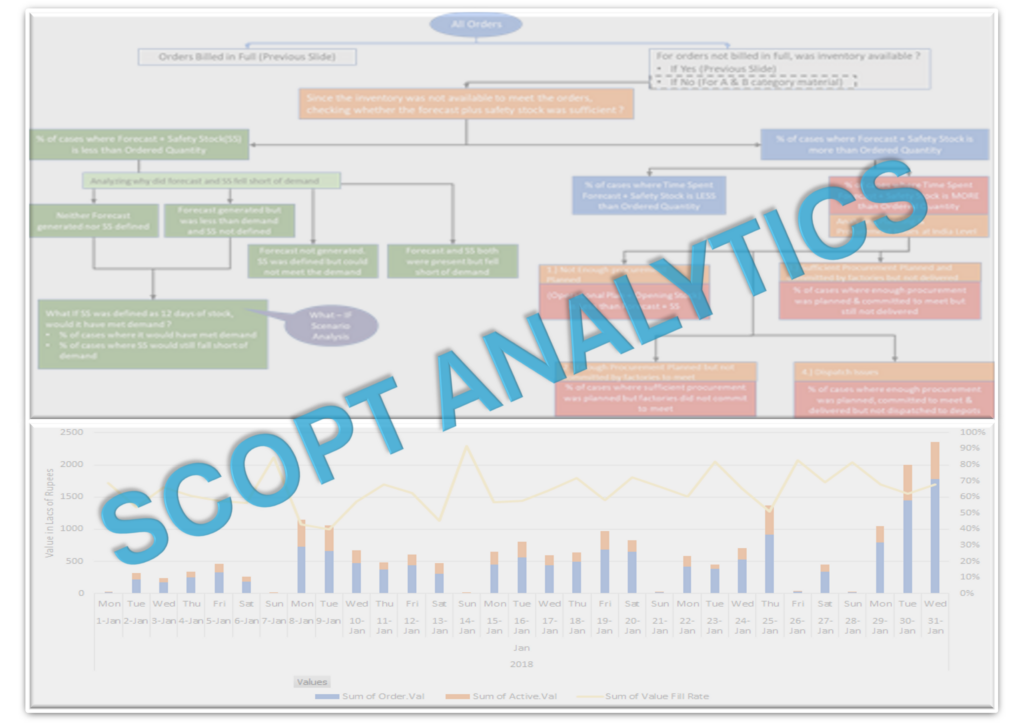

Business Challenge: A multinational electrical equipment company faced revenue leakage due to sub-optimal order fulfillment. They struggled to identify the root causes and implement corrective actions to improve fulfillment rates.

Solution: We developed a comprehensive hypothesis tree map to gain a 360° view of the order fulfillment process. By analyzing unfulfilled orders, we identified and attributed losses to specific non-fulfillment reasons. An automated solution was created to evaluate the impact of these causes on order fulfillment. Additionally, a what-if scenario tool was implemented to assess the effects of safety stock adjustments on fill rates. Analytical dashboards were also developed for daily fill rate analysis and decision support.

Business Results: Identified major causes of unfulfilled orders, including inaccurate forecasts and insufficient safety stock, and resolved issues like credit blocks for reliable partners. This led to a better understanding of demand volatility and more accurate safety stock levels.

India

Industry: Manufacturing

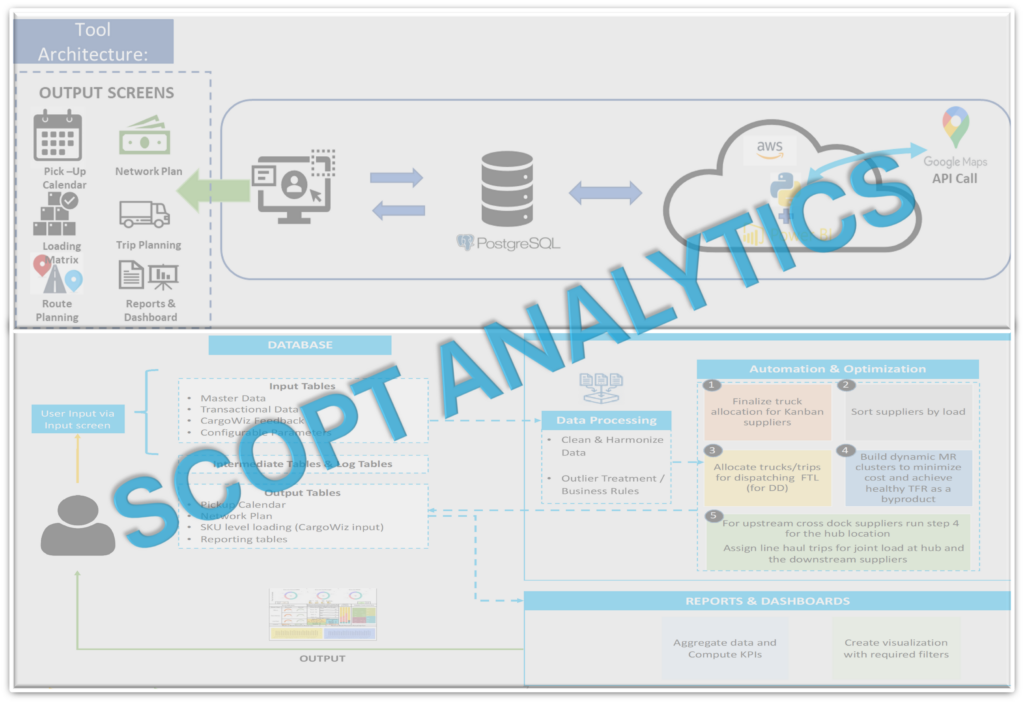

Business Challenge: A leading global commercial vehicle manufacturer faced significant challenges in its logistics operations due to the daily demand for parts from approximately 300 suppliers across India. The current system suffered from suboptimal truck utilization, with issues such as inefficient truck capacity usage and poorly planned routes. This resulted in increased costs for inbound logistics and hampered overall operational efficiency.

Solution: We implemented an automated vehicle and route planning solution that eliminated manual processes while retaining business rules. Key optimizations included selecting the right truck types, allocating trucks based on pickup windows, consolidating loads, and dynamically clustering suppliers for optimal routing. These strategies minimized logistics costs and improved operational efficiency.

Business Results: Optimized routes and minimized the number of trips by leveraging dynamic milk run opportunities. This led to improved truck fill rates exceeding 75% and enhanced visibility into asset utilization and availability, resulting in 5-10% cost savings for inbound logistics.

India

Industry: Consumer Packaged Goods (CPG)

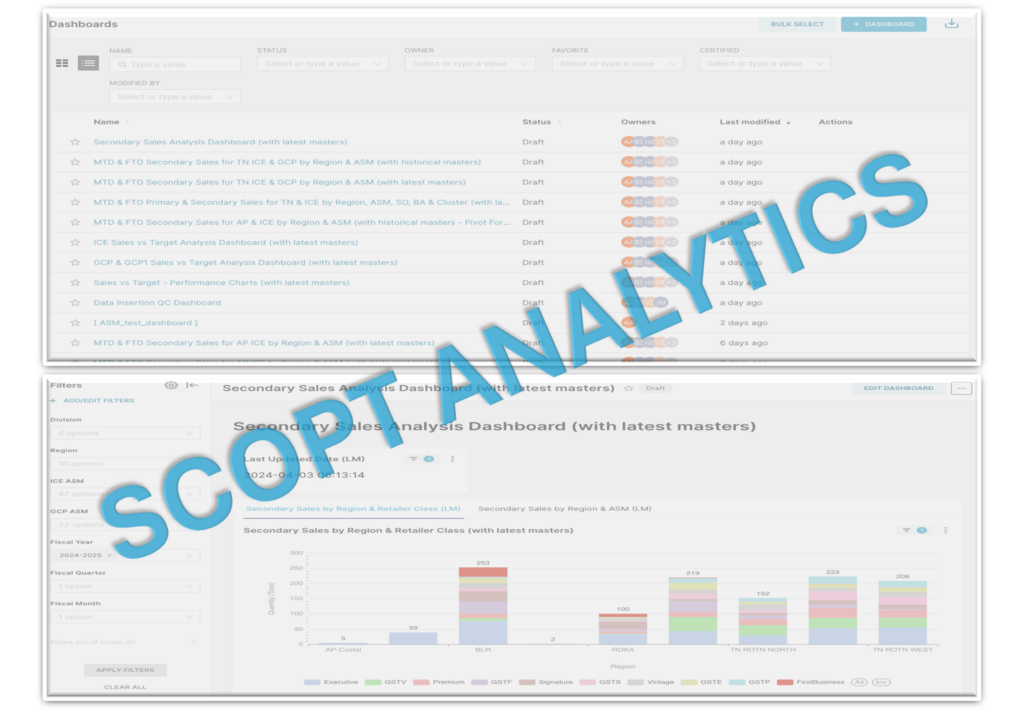

Business Challenge: A leading producer of cooking oils and dal products in South India faced significant challenges with its daily sales reporting process. Sales reports for the leadership team were generated manually using MS Excel, resulting in considerable effort, delays, and errors. Additionally, the lack of data democratization restricted sales teams from conducting in-depth data analysis in near real-time, hindering their ability to make informed decisions and respond swiftly to market demands.

Solution: To streamline sales reporting, we extracted and transformed transactional sales data from multiple sources into a PostgreSQL database on Google Cloud Platform (GCP). We designed a data mart to aggregate this data into key business metrics and automated the extraction, transformation, and aggregation processes using Apache Airflow scripts for improved efficiency and accuracy. Additionally, we configured Apache Superset for real-time access to the data mart, allowing for on-demand generation of charts and dashboards.

Business Results: The DIY platform empowered teams to analyze data, build ad-hoc dashboards, and unearth valuable business insights.

USA

Industry: Automotive

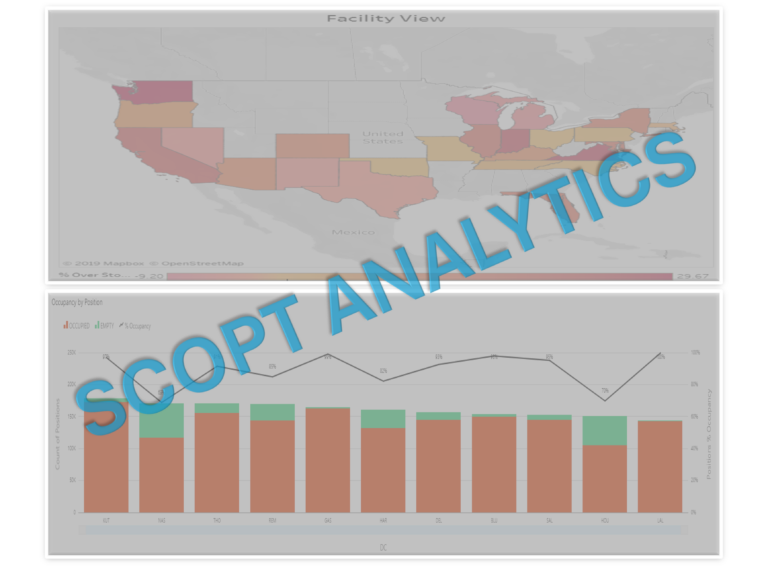

Business Challenge: An American automotive aftermarket parts provider faced challenges in obtaining visibility into overall capacity and utilization across its distribution centers (DCs). They needed a comprehensive view that included dollar value, pieces on hand, and cubic volume, which hindered their ability to optimize operations and make informed inventory management decisions.

Solution: We designed an integrated cloud-hosted data mart to consolidate large volumes of weekly data from various WMS systems across DCs. Using Python, we developed a compute engine to process and aggregate data for cubic utilization and occupancy metrics. Power BI was utilized for creating innovative visualizations, while the entire application was developed, hosted, and maintained on AWS for scalability and future-proofing.

Business Results: Business users were able to leverage DC utilization metrics across multiple product categories and align their procurement strategy with available capacity.

India

Industry: Manufacturing

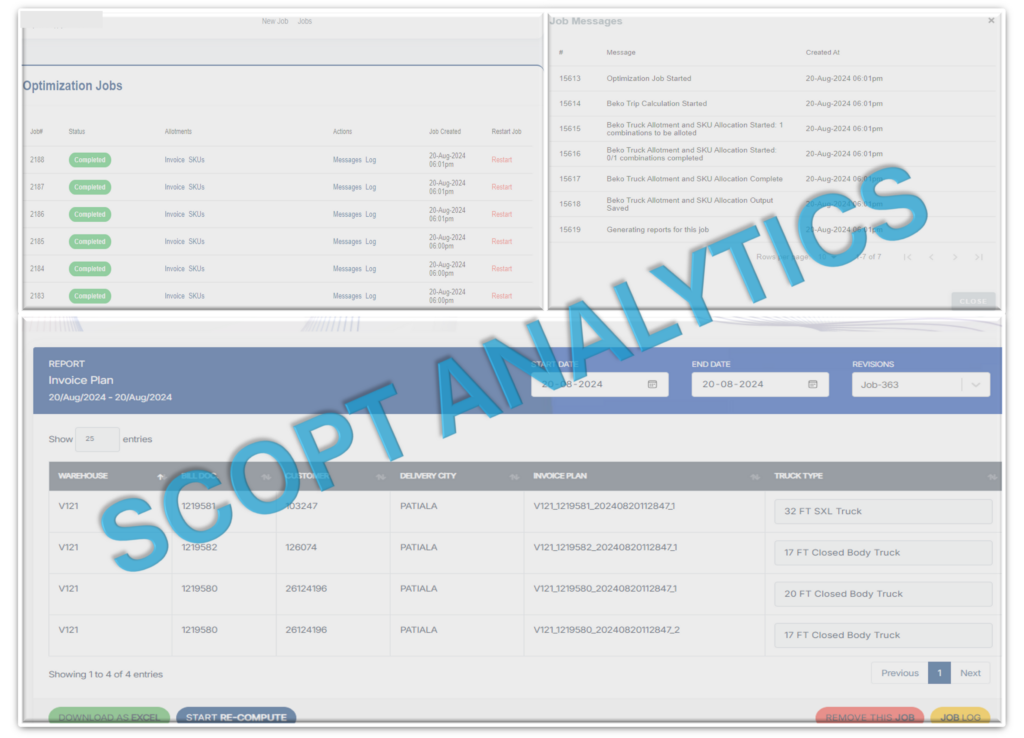

Business Challenge: A leading appliance manufacturer faced significant challenges in their invoice generation and logistics processes. They needed a streamlined method to instantly generate invoices for incoming orders while also calculating the optimal number of trucks required for delivery. Additionally, they faced the need to consolidate multiple orders into optimized trucks possible for final delivery, complicating logistics management and increasing operational costs.

Solution: We developed an automated invoice planning tool that generates plans based on incoming orders, factoring in quantity, weight, and volume to assign the optimal number of trucks. The tool includes options to recompute plans based on truck availability and integrates constraints like stacking and vehicle types. Additionally, an order consolidation engine was implemented to group multiple orders for efficient truck utilization and reduced logistical costs, with customizable options for delivery methods, truck types, and drop sequences.

Business Results: Significantly reduced the time required to generate invoices and plan deliveries, leading to faster order processing. Optimized truck usage resulted in decreased transportation costs due to fewer trips.

India

Industry: Fast Moving Electrical Goods (FMEG)

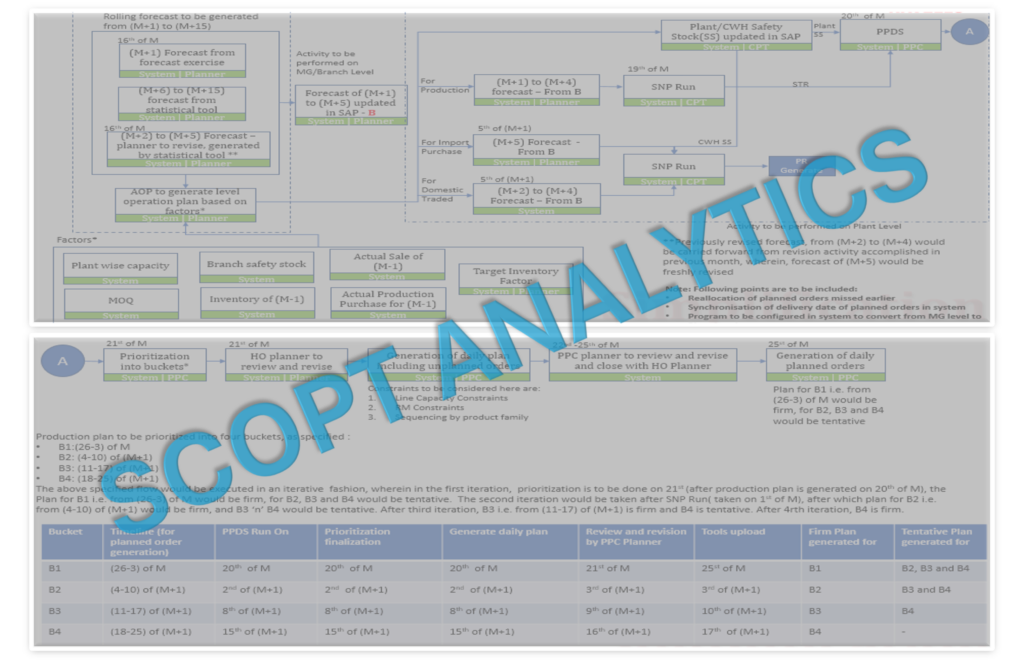

Business Challenge: A leading electrical goods company was unable to commit to delivery dates for orders due to a lack of a detailed production schedule. They needed an automated solution to generate a daily production plan and sequence by incorporating production orders and all relevant constrain.

Solution: We created an automated Python model to determine the most efficient daily production sequence, accounting for constraints like raw material availability, assembly line capacity, manpower, and business priorities. The model was optimized for the highest SKU mix. An additional on-demand model was developed to verify manual overrides against these constraints. The solution was deployed and integrated with the warehouse system.

Business Results: Automating the daily production sequence enabled the customer to accurately communicate delivery dates to end consumers. The system’s checks on manual overrides ensured high adherence to the recommended schedule and added discipline to the process.

USA

Industry: Automotive

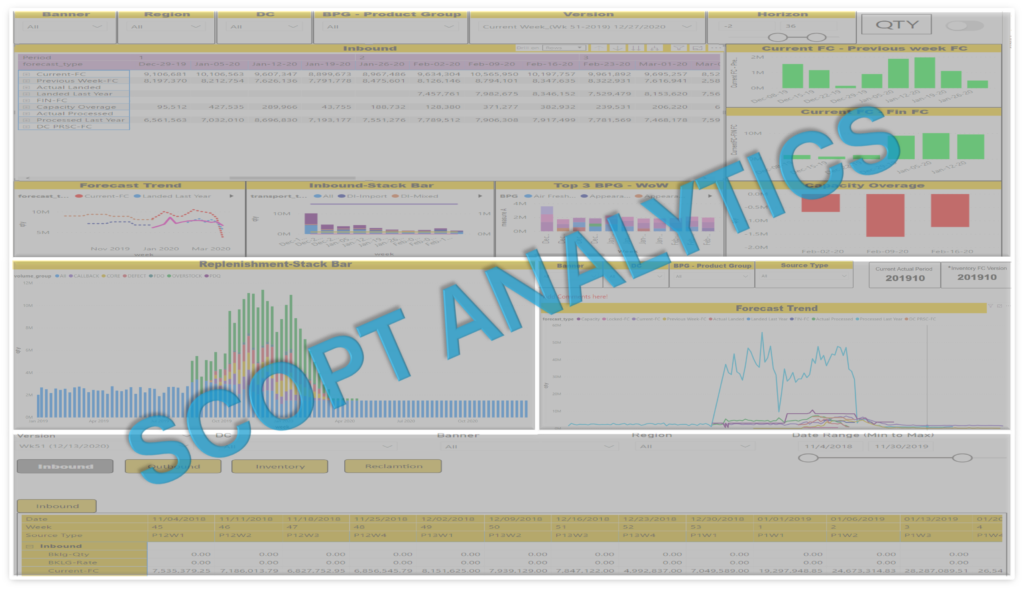

Business Challenge: An automotive aftermarket part provider needed a Sales and Operations Planning (S&OP) decision support system to enhance decision-making during weekly meetings and improve alignment between inventory, demand, and distribution center (DC) capacity.

Solution: We analyzed the “As-Is” business process to identify key metrics and indicators. A cloud-hosted data mart was designed to integrate diverse data sources, with Python pandas used for data analysis and building a business rules engine for projected shortfalls and KPIs. Extensive data wrangling supported various business scenarios, and near real-time visualizations in Microsoft Power BI enabled data-driven decision-making.

Business Results: The solution provided a comprehensive view of factors influencing operational decisions, including demand forecasts, available capacity, and inventory status. It computed key metrics such as weekly inventory shortfalls and highlighted high-risk areas and slow-moving inventory for corrective action.

India

Industry: FMCG

Business Challenge: Excel sheets were used to capture fleet operations data and circulated among stakeholders for taking operational decisions on logistics and fleet management. Noisy data captured in excel sheets across locations, missing values and data-type mis-matches etc, were some of the pain points. No unified view of combined metrics from different teams for managing fleet maintenance, operations and financials.

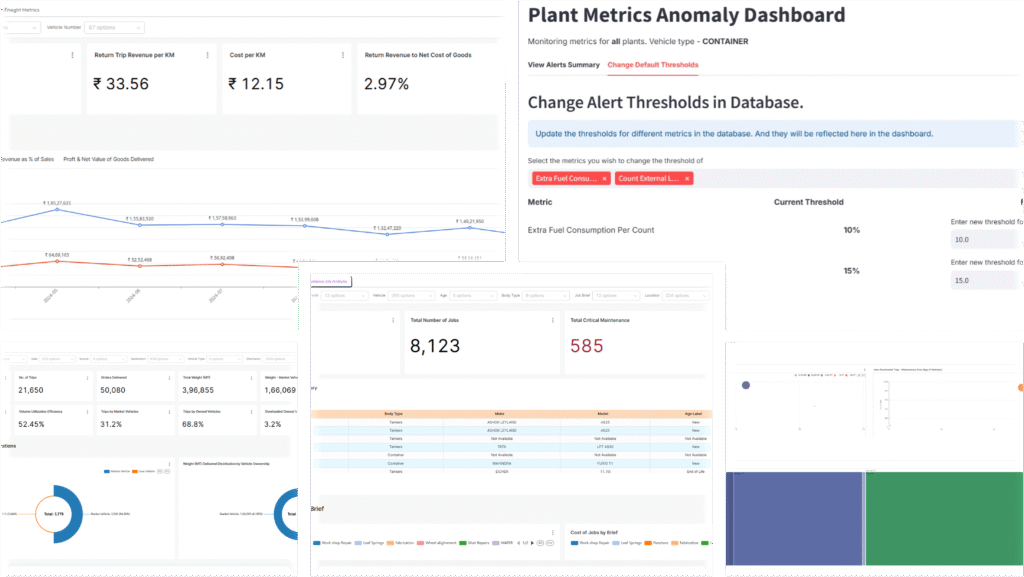

Solution: We developed dashboards using Apache Superset to showcase key business metrics for executive management regarding fleet maintenance, fleet operations and fleet financials. Data pipeline was created to extract data from disparate data sources (Excels and SAP) using Apache Airflow. Data cleanup and validation scripts were developed to unify, modify and normalize data as required. Generated insights around key business metrics like cost / km, revenue / km, freight cost as % of sales etc,. along various dimensions. Thresholds and notifications can be configured by business users to plan, engage and continuously improve logistics and fleet management operations

Business Results: Unified view of critical metrics with drill-downs across various dimensions. Strategic insights to make faster decisions on improving logistics and fleet metrics.