INVENTORY OPTIMIZATION FOR IMPROVED PRODUCT AVAILABILITY, CUSTOMER SATISFACTION, AND PROFITABILITY

RIGHT-PRODUCT at right-time, right-location, AND RIGHT-QUANTITY TO MEET CUSTOMER DEMAND EFFECTIVELY, WHILE OPTIMIZING COST

Inventory Management is a Challenge and an Opportunity

Demand volatility, supply chain complexity, manual processes and lack of data-driven approach can lead to significant inventory management challenges for your business.

- Demand Volatility: Rapid shifts in demand due to many factors can lead to stock imbalances and reduced customer satisfaction.

- Inefficient Inventory Turnover: Balancing between overstocking and stock-outs can result in high inventory holding costs or lost sale opportunities.

- Manual Processes: Outdated and manual inventory practices lead to human errors, slow replenishment cycles, and increased inventory carrying costs.

- Fragmented Inventory Data: Managing inventory across multiple locations and systems without real-time data causes operational inefficiencies.

Manage Your Inventory Balancing Holding Costs and Service Levels

Our solution aligns business processes, data insights and AI/ML models, to enhance inventory visibility, uncover hidden costs, mitigate risk and improve service levels

- Process Re-engineering: Evaluate the current ‘as-is’ inventory management processes to identify gaps or bottlenecks that hinder managing optimal stock levels. Analyze and tweak processes to reduce overstock situations, which can tie up working capital.

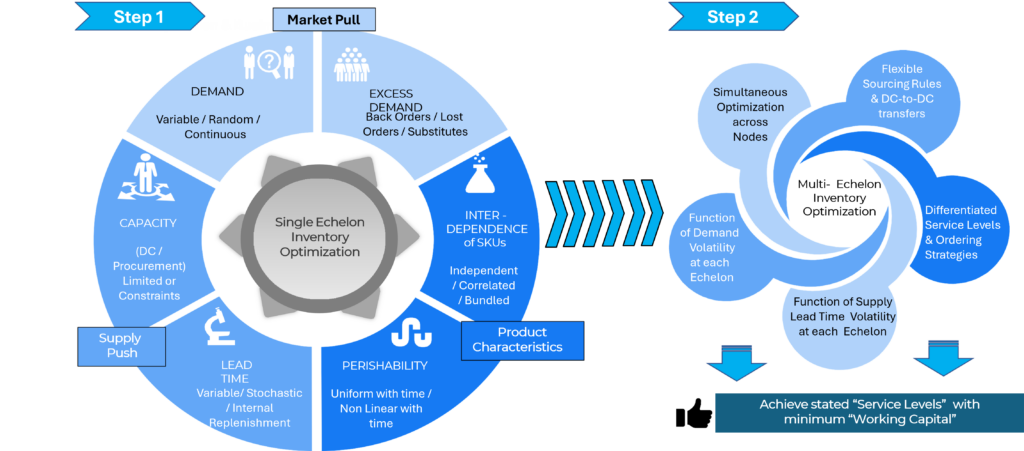

- Multi-echelon Inventory Optimization: Using AI/ML models, accurately predict demand peaks, enabling timely stock replenishment and avoiding over-stocking or under-stocking. Optimize inventory at a single echelon (like a warehouse) and then synchronized optimization of stock levels across multiple echelons in the supply chain, to balance service levels, lead times, and carrying costs.

- Inventory Metrics Optimization: Review and recommend best practices for inventory metrics such as days of supply (DOS), inventory turnover ratio, and carrying costs. Regularly monitor these metrics to identify where optimizations can be made.

Delivering Tangible Business Benefits

Our comprehensive solution encompassing process, data and system enables you to track orders, sales, stock and deliveries closely, thereby ensuring right product with the right quantity is available at the right time and location, improving your cash flows, profitability and customer satisfaction.

- Our solution delivers the following benefits

- Reduces Inventory Carrying Costs: By optimizing stock levels, you lower the costs associated with warehousing, such as storage, insurance, and obsolescence.

- Prevents Stockouts and Overstocking: Ensures optimal stock levels, reducing lost sales from stockouts and preventing excess stock, which ties up working capital.

- Improves Order Fulfillment Speed and Accuracy: By having the right stock in the right location, order fulfillment becomes faster and more accurate, reducing lead times.

- Improves Supplier Relationships: Maintaining optimal inventory levels allows for smoother procurement processes, better negotiations, and bulk discounts with suppliers.

- Enhances Cash Flow: Optimized inventory helps maintain a leaner inventory, freeing up cash that can be reinvested into other parts of the business.

INVENTORY OPTIMIZATION SOLUTION