Unlocking Transport Logistics Optimization for Inbound and Outbound Supply Chains

Written By

Arun Dev Kumar, Manager – Supply Chain Solutions & Products.

25th September 2024

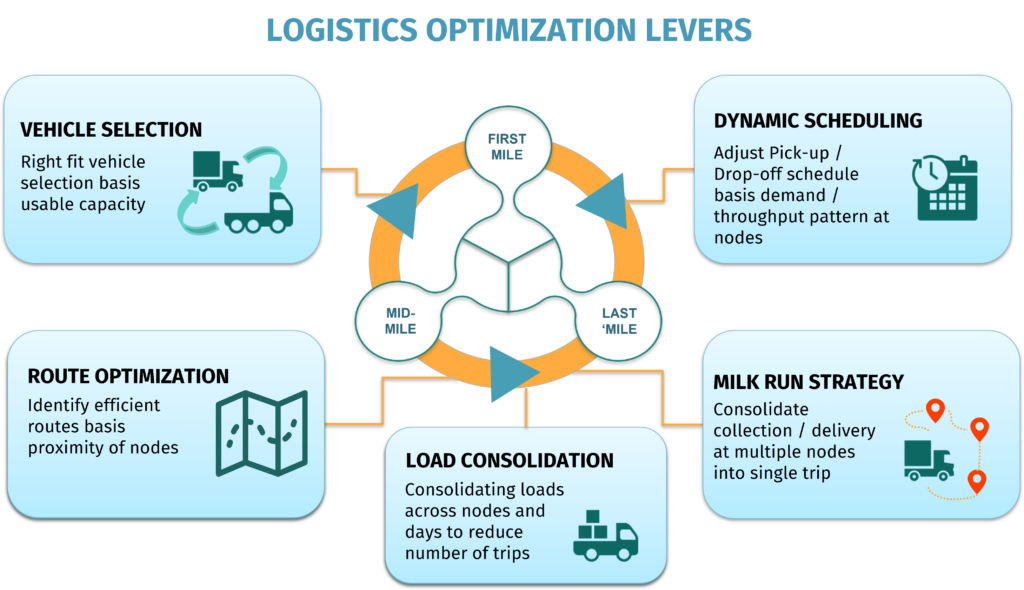

We explore the levers that are pivotal for optimizing inbound and outbound logistics operations, with a focus on critical constraints such as delivery window adherence, route and load optimization, vehicle selection, and dynamic scheduling.

- Increasing Complexity of Last-Mile Deliveries: With e-commerce and retail businesses offering faster delivery services, the complexity of last-mile logistics has dramatically increased. This has necessitated investment in advanced route optimization and dynamic scheduling tools.

- Inbound Logistics -Managing Multiple Suppliers: Large-scale industries like automotive and consumer electronics face the challenge of managing numerous suppliers spread across geographies. Ensuring timely pickup, adhering to delivery windows, and consolidating loads for reduced transportation costs are critical issues.

- Outbound Logistics – Balancing Customer Expectations and Cost: For industries like FMCG and retail, meeting customer demand while minimizing transportation costs can be a balancing act. Cross-docking, Milk Run strategies, and leveraging load consolidation are important solutions that must be tailored for high throughput environments like supermarkets.

- Constraints in Modern Transport Logistics: Strict delivery time windows, stacking limitations due to product fragility, and driver availability are just a few of the constraints that modern supply chains must navigate.

- Vehicle Selection: The right-fit vehicle selection, based on usable capacity and type of goods being transported, is crucial to reducing overall logistics costs. In industries like e-commerce or FMCG, choosing between smaller, more agile vehicles for urban deliveries and larger trucks for regional distribution hubs can significantly impact cost efficiency. Example: Leading grocery chains like Walmart have partnered with logistics providers to ensure that delivery vehicles are optimized for the load mix and route length, using smaller vehicles for urban fulfillment centers and larger trucks for regional distribution centers.

- Route Optimization: Identifying the most efficient routes based on proximity to distribution centers, road conditions, and customer locations is key to reducing travel time and fuel costs. Companies like Amazon rely heavily on AI-driven route optimization tools to dynamically re-route vehicles based on real-time traffic data and delivery windows. Example: Amazon’s route optimization algorithms help the company cut down delivery times by mapping out the most efficient paths, reducing both fuel costs and delivery delays.

- Milk Run Strategy: The Milk Run strategy, where vehicles make multiple pickups or deliveries along a single route, is an effective way to reduce transportation costs, particularly for short-to-medium-range deliveries. It allows logistics operators to reduce empty vehicle returns and maximize vehicle capacity. Example: One of India’s leading commercial vehicle manufacturer’s use of Milk Run logistics to collect parts from 300+ suppliers in India is a textbook case of optimizing inbound logistics. The strategy reduces the number of trips while ensuring that production lines remain uninterrupted leveraging JIT deliveries.

- Dynamic Scheduling: Dynamic scheduling is the ability to adjust pickup and delivery schedules in real-time, accommodating fluctuating demand, stock levels, and throughput patterns at nodes. This lever helps logistics providers adjust delivery times on the fly, ensuring that high-priority orders are fulfilled first. Example: DHL’s SmartTrucking platform uses dynamic scheduling to ensure flexible delivery windows across their transportation network, improving service levels by 15% in regions with high congestion.

- Load Consolidation: Consolidating loads across nodes and days is an effective way to reduce the number of trips, increase vehicle utilization, and lower transportation costs. It is especially important in industries like manufacturing where raw materials or components need to be collected from multiple suppliers and delivered to a central plant. Example: A leading commericial vehicle manufacturer in India employs advanced load consolidation techniques and algorithms, reducing the number of vehicles needed for inbound deliveries and realizing network cost savings of upto 5% month on month.

- Delivery Window Compliance: In sectors like e-commerce and retail, adherence to strict delivery windows is essential to maintaining customer satisfaction. For inbound logistics, failure to meet these windows can disrupt manufacturing operations. This constraint demands highly accurate scheduling and route planning to avoid penalties and service degradation.

- Stacking and Load Constraints: Proper stacking and loading are essential, especially for goods that are fragile or have specific handling requirements. In the food and pharmaceutical industries, where goods must be transported at specific temperatures, improper stacking can lead to product spoilage.

- Maximum Travel Distance for Milk Runs: While Milk Run operations are effective for shorter distances, they can become inefficient over longer routes. To ensure cost savings, it’s essential to calculate the maximum allowable distance for each Milk Run without sacrificing delivery times or product quality.

- Driver Availability and Legal Constraints: With regulations on driver working hours and rest periods, logistics operations must factor in driver availability when planning routes and delivery schedules. Tools that provide real-time visibility into driver schedules and vehicle status are critical to overcoming this challenge.

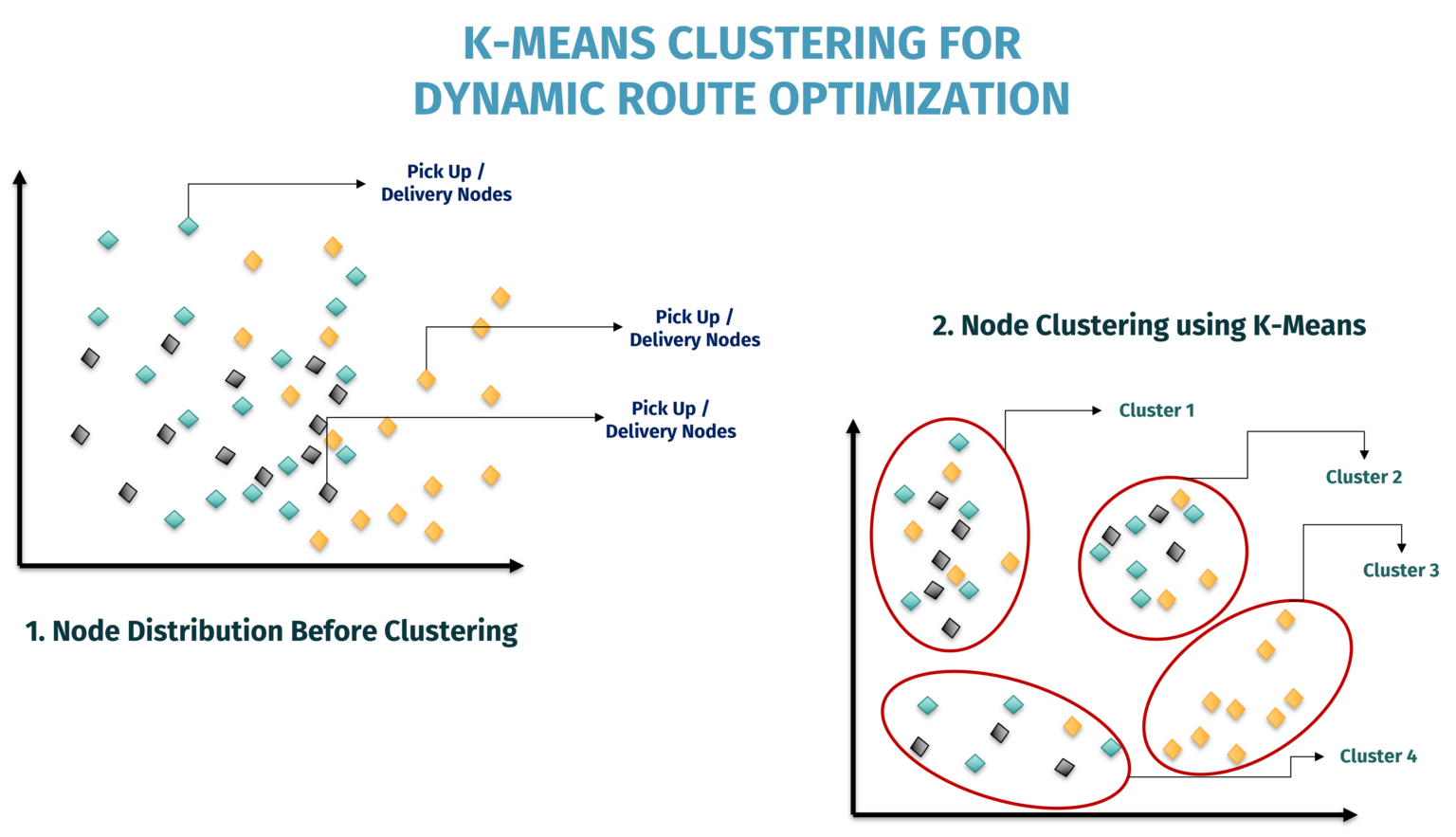

- Artificial Intelligence (AI) and Machine Learning (ML) based route optimizaiton: AI and ML algorithms provide real-time route recommendations:

- Leveraging K-Means Clustering, delivery or pickup points can be grouped based on proximity. By clustering nearby stops into geographic regions, logistics managers can minimize travel distances and optimize vehicle routes.

- Genetic Algorithms (GA) are search heuristics that can solve complex optimization problems like Traveling Salesman Problem (TSP), which aims to find the shortest route to visit a series of locations and return to the origin. When time constraints are added, GAs help logistics teams find the most efficient routes that meet time window restrictions for each delivery or pickup point.

- The Vanning Problem (or loading problem) involves determining the most efficient way to load items into a vehicle, adhering to constraints such as vehicle capacity, stacking rules, and weight distribution. This can be solved using Constraint Satisfaction Problems (CSP) and Linear Programming (LP), which optimize the packing of goods while respecting operational constraints.

- Telematics and IoT: Telematics and IoT devices are vital enablers of real-time visibility in transport logistics. By collecting and analyzing data on vehicle location, fuel consumption, and driver behavior, these systems provide valuable insights for route optimization and vehicle utilization. Additionally, IoT sensors monitor load conditions, such as temperature and humidity, which are critical for perishable goods, ensuring compliance with safety standards and reducing product spoilage. Constraint Alleviation: Telematics systems address issues such as driver availability and vehicle breakdowns by alerting operators in real time, enabling them to adjust routes or reassign vehicles, thereby maintaining operational continuity.

- Blockchain for Supply Chain Transparency: Blockchain provides real-time, tamper-proof records across the logistics network, reducing administrative burdens, preventing fraud, and ensuring compliance with delivery times and product integrity. Constraint Alleviation: By leveraging blockchain, businesses can reduce inefficiencies caused by manual tracking and paperwork, ensure compliance with delivery windows, and build trust across the logistics network. Moreover, it helps prevent fraud and enhances accountability, crucial for high-value and sensitive shipments.

Transport logistics optimization is an ongoing challenge for industries across the board, from e-commerce and retail to large-scale manufacturing. By leveraging key levers such as vehicle selection, dynamic scheduling, and Milk Run strategies, companies can significantly improve their transport operations, reduce costs, and enhance customer satisfaction. Advanced technologies like AI, IoT, and blockchain are driving the next generation of logistics solutions, enabling real-time decision-making and enhanced visibility across supply chains. For businesses looking to remain competitive, optimizing inbound and outbound logistics is not just an option—it is a necessity.